In keeping with our corporate philosophy, “Otsuka-people creating new products for better health worldwide,” and the Otsuka values of Ryukan-godo (by sweat we recognize the way), Jissho (actualization), and Sozosei (creativity), we strive every day to do what only Otsuka can do. In this way, the Otsuka group contributes to the lives of people worldwide through innovative and creative products and services including pharmaceuticals, functional beverages and functional foods.

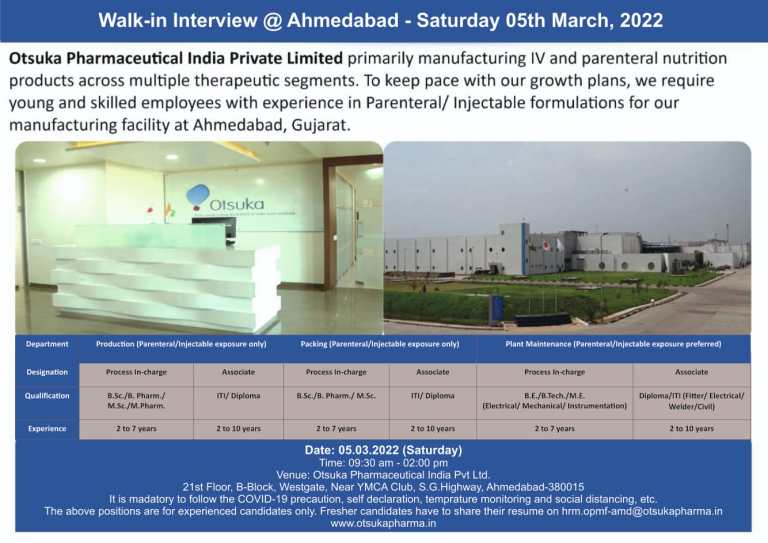

Vacancy Details

*For Production (Parenteral/Injectable exposure only):

>Process In-charge: (B.Sc./M.Sc./B.Pharm./M.Pharm.):

- – To ensure the cleanliness, environmental norms and other process of various area like Dispensing, Mixing, Filling and Terminal Sterilizer.

- -To complete CIP, SIP and batch manufacturing process timely.

- -To ensure the batch manufacturing process is done as per Batch Manufacturing record.

- -To co-ordinate with other departments like QA, QC, Stores, Engineering, etc. as and when required.

>Associate (Machine Operator): (ITI/Diploma):

- -To monitor temperature / humidity of clean rooms, and if any deviation is found, inform the Engineering department.

- -To ensure cleaning and disinfections of floor, ceiling, wall, pipeline, vessels and equipment as per frequency defined.

- -To maintain the cleaning and lubrication of machine regularly.

- -To ensure the machine is working smoothly and it is performing well..

*For Packing (Parenteral/Injectable exposure only):

>Process In-charge: (B.Sc./M.Sc./B.Pharm.):

- –To make sure that issued material is as per requirement and the material quality is as per specification.

- -To check the availability of packing material with proper labels and status.

- -To ensure that the packing activity does not start without line clearance.

- -To check, verify and destroy the rejection generated during packing and ensure recording of all such material.

- -To update the Batch Packing Record on line.

- -To check the packing online at frequent intervals as defined in the Standard Operating Procedure.

- -To train personnel for the critical operations like visual inspection and labeling.

>Associate (Machine Operator): (ITI/Diploma):

- -To maintain the machine in good condition by regular cleaning and lubrication.

- -To ensure that machines are working smoothly and performing as per standards.

- -To supervise the packing activities online at frequent intervals as defined in the Standard Operating Procedure (SOP).

- -To ensure that the machine/s are started within time period & perform challenging test.

*For Plant Maintenance (Parenteral/Injectable exposure will be preferred):

>Process In-charge: (B.E./B.Tech./M.E. (Electrical/ Mechanical/ Instrumentation)

- -To prepare monthly Preventive Maintenance (PM) Schedule.

- -To verify spares.

- -To observe PM activity and prepare PM review report.

- -To verify PM checklist & equipment operation logbooks.

- -To maintain documentation system in compliance with Current Good Manufacturing Practice (cGMP) norms.

>Associate (Fitter/Electrician/Welder/Civil): ( Diploma/ITI (Fitter/ Electrical/ Welder/Civil))

- -To perform Preventive Maintenance (PM) of equipments as per schedule.

- -To perform task as allocated.

- -To escort supplier / service provider personnel for maintenance.

- -To follow safety precautions during maintenance.

- – Can handle tools and tackles such as drilling machines, cutting machines, plumbing work and other building maintenance activities.

Candidate Profile :-

- Ready to work in rotational shifts.

- Excellent understanding about working area.

- Initiator and Learner.

- Decision making ability.

- Team player and if required, can provide training to other team members.

- Good communication.

The above positions are for shift (rotational) operations and only for experienced candidates. Fresher candidates have to share their resume on hrm.opmf-amd@otsukapharma.in

Date: 5th March, 2022

Time: 9.30 AM – 2.00 PM

Venue:Otsuka Pharmaceutical India Pvt. Ltd21st Floor, B-Block, Westgate, Nr. YMCA, S.G Highway,Ahmedabad – 380 015